Plastic Injection Molding

Guan Lin Industrial Co., Ltd. is the leading Taiwan manufacturer, supplier and exporter of Plastic Injection Molding which is engineered from the best quality raw material and are acknowledged for their sturdy construction and durable service life. In order to ensure their longer service life and quality we manufacture these products using top grade raw material as per the international quality standards. We are exclusively offering these products in wide range of vibrant colors patterns and sizes and are also customization as per the client's requirements. Our products are also known for their excellent quality, prompt service and reasonable price.

Plastic Injection Molding

Model - 7-3

Global Recycled Standard (GRS) Certificate

The Global Recycled Standard (GRS) is a certification mechanism belonging to Control Union (CU). Its primary objective is to ensure that manufacturers claiming to produce environmentally friendly products utilize GRS-certified materials. Besides, the certificate ensures that manufacturers and traders adhere to regulations associate with quality management, social responsibility, chemical management and environmental management.

In order to ensure the authenticity of a recycled product, the GRS requests material suppliers to upload purchase orders, delivery notes and invoices to the GRS online system. This process enables them to provide transaction certificate (TC) for the next processor. Consequently, every supplier involved in the supplier chain of an environmentally friendly product must possess GRS certificate to enable the last processor of the product to provide TCs to end buyers.

By receiving TCs or observing GRS label on goods, both brand clients and consumers can be confident that the products they are purchasing are truly environmentally friendly. These TCs and labels serve as tangible evidences proving that the products are manufactured using GRS-certified materials and that the entire supply chain has met the required GRS-related standards.

The Global Recycled Standard (GRS) is a certification mechanism belonging to Control Union (CU). Its primary objective is to ensure that manufacturers claiming to produce environmentally friendly products utilize GRS-certified materials. Besides, the certificate ensures that manufacturers and traders adhere to regulations associate with quality management, social responsibility, chemical management and environmental management.

In order to ensure the authenticity of a recycled product, the GRS requests material suppliers to upload purchase orders, delivery notes and invoices to the GRS online system. This process enables them to provide transaction certificate (TC) for the next processor. Consequently, every supplier involved in the supplier chain of an environmentally friendly product must possess GRS certificate to enable the last processor of the product to provide TCs to end buyers.

By receiving TCs or observing GRS label on goods, both brand clients and consumers can be confident that the products they are purchasing are truly environmentally friendly. These TCs and labels serve as tangible evidences proving that the products are manufactured using GRS-certified materials and that the entire supply chain has met the required GRS-related standards.

Due to a great variety of

Plastic Injection Molding

let our commodities go to the world. We can provide you the reasonable price and perfect after-sales service. Welcome the new and old customers to visit our company.Enquiry Now

Products List

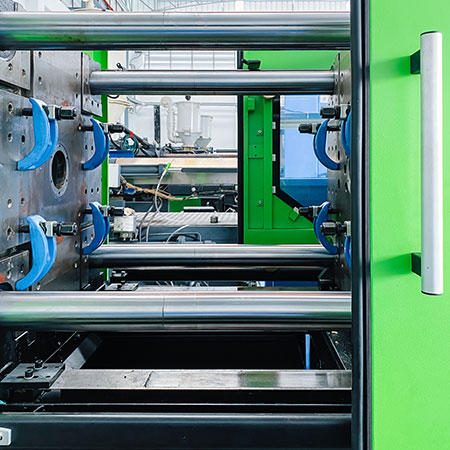

Introduction of Plastic injection molding machine

Plastic injection molding department of Guan Lin Industrial has remained steadfast in the commitment to delivering high quality services to a diverse range of industries since the establishment in 2020. With a focus on precision and reliability, Guan Lin Industrial has emerged as a trusted partner for numerous enterprises. The end applications include enclosures of electronic devices, sports equipment, other plastic goods.

In order to meet the increasing demands of clients and ensure continuous satisfaction, Guan Lin Industrial has been constantly expanded machinery and testing equipment. This investment is driven by the commitment to fulfilling requirements of clients and maintaining the position as a reliable partner in the plastic injection molding industry.

In addition, in response to the global trend of reducing plastic waste, Guan Lin Industrial has incorporated biodegradable material and GRS-certified post-consumer recycled materials in injection molding process to support the idea of lowering plastic consumption and promoting sustainability.

Through the unwavering focus on delivering high quality products, embracing sustainability initiatives, and investing in expanding production capabilities, Guan Lin Industrial aims to not only meet but exceed customer expectations.

Introduction of Plastic injection molding materials

Guan Lin Industrial provides clients with numerous choices in materials. In addition to general purpose plastics, clients can select biodegradable material and GRS-certified post-consumer recycled (PCR) materials. The diverse options in material allow clients to align their product choices with their sustainability objectives.

In response to growing global concerns in carbon emissions, several countries are imposing stricter regulations. The European Union, in particular, has enacted legislation that would impose carbon import taxes on goods entering the EU in 2026. The primary aim of the tax is to hold manufacturers accountable for the carbon dioxide emitted throughout their manufacturing processes. In order to clearly understand the total carbon emitted of a factory, manufacturer can conduct a carbon footprint assessment involves calculating the amount of carbon emitted based on several factors, including materials used, energy consumed in production processes and transportation involved and more. This assessment will provide a comprehensive picture of carbon emissions of the entire manufacturing process which aid in identifying the specific portion of a manufacturing process that consumes unnecessary energy and emitted additional amounts of carbon.

From the perspective of material, due to the lack of energy consumed in refinement of crude oil, GRS-certified PCR material emitted less carbons comparing to other petro-based materials. This leads to better product competitiveness because of lower carbon import tax.

The plastic injection molding department of Guan Lin Industrial has continuously focused on the development and enhancement of plastic injection molding techniques. Guan Lin Industrial offers clients comprehensive OEM/ODM services, including mold design and development, injection molding, product assembly, screen printing, packaging and shipping.

At Guan Lin Industrial, clients are presented with an extensive range of material options to choose from. These materials are classified into three categories: general plastics, post-consumer recycled (PCR) and biodegradable material. For clients who prioritize environmental protection and low-carbon solutions, PCR materials serve as ideal options. On the other hand, for disposable applications, biodegradable material offers an excellent solution. Clients have the flexibility to choose the most suitable materials that suit their specific needs.

In addition to ensuring quality and meeting deadline, Guan Lin Industrial is also committed to conserving the nature and the environment with clients. Clients who collaborate with Guan Lin Industrial can not only rely on our expertise and exceptional services, but they can also align themselves with an environmentally friendly strategy. Guan Lin Industrial cooperates with clients to create a sustainable future and have a positive impact on the globe. This dedication has earned Guan Lin Industrial the reputation of being a trusted and influential partner for numerous enterprises.

English

English Français

Français Deutsch

Deutsch Русский

Русский Português

Português Italiano

Italiano हिन्दी

हिन्दी Español

Español Nederlandse

Nederlandse العربية

العربية Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Bahasa Indonesia

Bahasa Indonesia বাঙ্গালী

বাঙ্গালী Türk

Türk 繁體中文

繁體中文