Recycled PET Yarn

Recycled PET Yarn Manufacturers, Suppliers-Guan Lin Industrial Co., Ltd.

Guan Lin Industrial Co., Ltd. is the leading Taiwan manufacturer, supplier and exporter of Recycled PET Yarn, our products is sourced from reliable vendors of market, who use superior quality raw material in the manufacturing process. In order to ensure their longer service life and quality we manufacture these products using top grade raw material as per the international quality standards. We are offering the device our clients' at the most affordable prices. We are best known for satisfying customers with the efficiency and long last lasting ability of our products. Owing to the quality, these products are demanded across the globe.

Guan Lin Industrial Co., Ltd. is the leading Taiwan manufacturer, supplier and exporter of Recycled PET Yarn, our products is sourced from reliable vendors of market, who use superior quality raw material in the manufacturing process. In order to ensure their longer service life and quality we manufacture these products using top grade raw material as per the international quality standards. We are offering the device our clients' at the most affordable prices. We are best known for satisfying customers with the efficiency and long last lasting ability of our products. Owing to the quality, these products are demanded across the globe.

To find and shop the Recycled PET Yarn, you need to know about the highest quality of Recycled PET Yarn manufacturer, supplier, wholesaler and distributor from a factory in Taiwan.

We're constantly looking for new ways to improve the way we work and pass the savings on to you. That's why we've been working closely with suppliers to ensure we have

We're constantly looking for new ways to improve the way we work and pass the savings on to you. That's why we've been working closely with suppliers to ensure we have

Recycled PET Yarn

to offer than ever before and at the best prices.Recycled PET Yarn

Model - 2-3

GRS (Global Recycled Standard) Certificate

GRS Certificate

In our unwavering dedication to environmental preservation and meeting the diverse demands of our valued clients, Guan Lin Industrial proudly attained the Global Recycled Standard (GRS) Certificate in 2018. After obtaining GRS certificate, we have remained steadfast in adhering to the rigorous regulations encompassing quality management, chemical management, social policies and environmental management. At every step of the way, our operations undergo meticulous on-site audits to ensure seamless alignment between the provided documentations and our actual practices. Through our unwavering commitment, we not only ensure the utmost reliability and authenticity of our recycled monofilament but also guarantee their resolute commitment to environmental and social responsibility.

GRS Certificate

In our unwavering dedication to environmental preservation and meeting the diverse demands of our valued clients, Guan Lin Industrial proudly attained the Global Recycled Standard (GRS) Certificate in 2018. After obtaining GRS certificate, we have remained steadfast in adhering to the rigorous regulations encompassing quality management, chemical management, social policies and environmental management. At every step of the way, our operations undergo meticulous on-site audits to ensure seamless alignment between the provided documentations and our actual practices. Through our unwavering commitment, we not only ensure the utmost reliability and authenticity of our recycled monofilament but also guarantee their resolute commitment to environmental and social responsibility.

Enquiry Now

Products List

GRS-Certified Monofilament

GRS Certificate

Nowadays, recycling plastic bottles and other post-consumer plastic merchandises to manufacture yarns and monofilaments is becoming a trend. Many brand clients have started to gradually replace virgin monofilaments with recycled ones to lower the impact of carbon emissions on the environment. The application of recycled monofilaments not only lowers carbon emissions and consumes non-decomposable waste but also enhances the corporate image and competitiveness of a company.

Due to the rising trend of eco-friendly products, obtaining GRS certificate in advance and starting to develop products with recycled monofilaments can provide a competitive advantage when seeking partnerships with brand clients. As a third-party certification body, the GRS provides credible documents and certification tags for GRS-certified products. This allows customers and brand clients to believe that both the composition and production processes of recycled monofilaments strictly comply with GRS-related regulations.

Material: GRS Certified Pre/Post-Consumer Recycle Polyester and Nylon

Color: Transparent or customized color

Country of Origin: Taiwan

Cross Sectional shape: Circle, triangle and flat

Diameter: 0.08mm~1.0mm

Denier: 60D~10000D

Physical Properties: breaking strength/Elongation and hot air/boiling water shrinkage

Main Application: Footwear, curtain, air/water filter and so on

What is GRS (Global Recycled Standard) Certificate?

GRS Certificate

The Global Recycled Standard (GRS) is a recycled product monitoring mechanism established by the Control Union in 2008. Since 2011, the ownership of GRS has been transferred to the Textile Exchange. GRS was established to ensure the materials and production processes applied to recycled products are environmentally and socially friendly. The monitoring mechanism includes four main management systems: quality management, chemical management, social management and environmental management.

Quality management

The main purpose of quality management system is to monitor the balance between the materials purchased and the products manufactured. Common mistakes such as inputting non-corresponding material, using recycled material in wrong machine or delivering wrong products to clients can occur. To avoid these mistakes, every supplier in the supply chain of recycled products is required to be GRS-certified to ensure the production process meet standards of GRS.

Chemical Management

The chemical management system mainly regulates substances that are harmful to the environment or human health. Currently, the list of regulated substances includes those specified by REACH and RoHS. Therefore, materials, dyes, solvents, and spinning oil containing harmful substances on these lists are not allowed to be used in production processes of GRS-certified products.

Social Management

In addition to complying with local laws regarding salary, and working hours, the social management system also establishes standards to monitor the working environment for employees. These standards monitor aspects such as drinking water, fire facility inspection, fire drills and more.

Environment Management

The environmental management system is responsible for regulating whether wastewater, exhaust gas and waste were properly treated before being discharged or discarded. Additionally, a transaction certificate (TC) should be provided for every transaction related to manufacturing GRS-certified products. The function of TC is to prove that a product is manufactured following GRS standards.

GRS certificate provide a fair and objective monitoring mechanism that allows costumers, retailers and brand clients to clearly understand that the composition and production processes of GRS-certified products are environmentally and socially friendly.

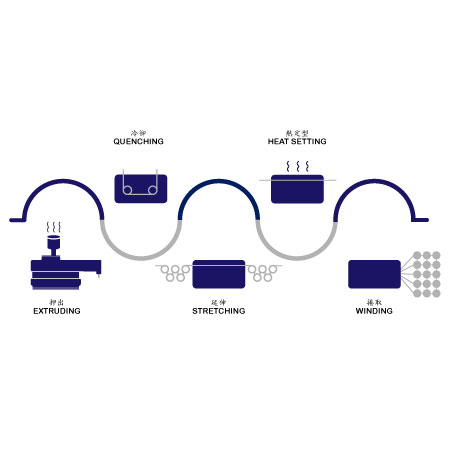

Production Flow of Monofilament

When plastic pellets or recycled pellets are fed into the extruder, they will be melted due to the heat present in the extruder chamber. Once the raw materials or recycled pellets are melted, they will be extruded by the extruder and cooled down at the quenching stage. During the stretching and heat setting stage, the physical properties of the monofilament can be adjusted to meet the requirements of clients’ applications. These physical properties of monofilament include breaking strength, elongation at break, hot air/boiling water shrinkage and among others. Finally, at the winding stage, clients have the option to choose from different types of tubes such as paper tube, metal tube and H tube based on their preference. Guan Lin Industrial prioritizes listening to clients’ demands and strives to provide tailored solutions that meet their unique requirements.

English

English Français

Français Deutsch

Deutsch Русский

Русский Português

Português Italiano

Italiano हिन्दी

हिन्दी Español

Español Nederlandse

Nederlandse العربية

العربية Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Bahasa Indonesia

Bahasa Indonesia বাঙ্গালী

বাঙ্গালী Türk

Türk 繁體中文

繁體中文