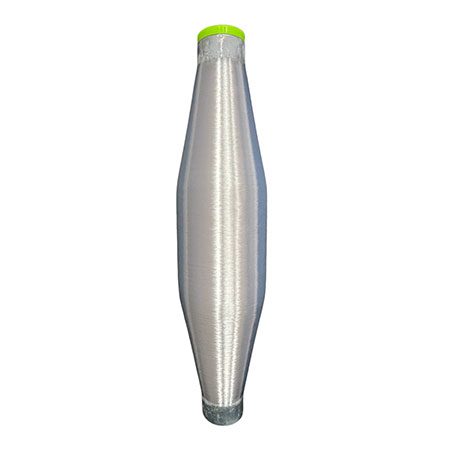

Thermoplastic Polyester Elastomer TPEE

We are a professional Thermoplastic Polyester Elastomer TPEE manufacturer, supplier and exporter, with more than years of years of experience, the factory in Taiwan We focus on this product can be customized according to customer demand. Any quantity is welcomed. With agressive attention, we can always offer you newest items in the market, with best price and service.

Thermoplastic Polyester Elastomer TPEE

Model - 3-3

Characteristics of TPEE

TPEE is an abbreviation for thermoplastic polyester elastomer. It is a copolymer of hard segments of polyester and soft segments of polyether. This allows TPEE monofilament to possess both strength and flexibility. In addition, there are four other features of TPEE monofilament:

TPEE is an abbreviation for thermoplastic polyester elastomer. It is a copolymer of hard segments of polyester and soft segments of polyether. This allows TPEE monofilament to possess both strength and flexibility. In addition, there are four other features of TPEE monofilament:

- Fatigue Resistant: TPEE possess great fatigue resistant and elasticity. After being stretch and released continuously, the physical properties of TPEE monofilament remain stable

- Abrasion Resistant: The excellent elasticity and resilience characteristics enable the monofilament to quickly return to its original state when subjected to pressure or friction. This will reduce the degree of abrasion

- Low-Temperature Flex Resistance: Even under low-temperature environment, TPEE monofilament still maintains great elasticity and flexibility

- Chemical Resistant: The physical properties of TPEE monofilament remain stable when it comes into contact with solutions, acid、oil and other substances

Our strength lies in our belief that technology should serve people and not the other way round. We drive technology and push it over the cutting edge to fulfill your

Thermoplastic Polyester Elastomer TPEE

to add quality to your life.Enquiry Now

Products List

Why is TPEE monofilament Chosen?

Many Countries are encountering textile waste and recycling difficulties due to recent fast fashion consumerism, especially developing countries that receive tens of thousands of tons of used clothes and shoes annually. These goods cannot be recycled or processed easily because the usage of composite or mixture of several different kinds of material.

However, if a single material or materials from the same family are utilized, treating the entire pair of shoes or garment as a single unit for recycling purposes can provide a viable solution to this problem. For example, if the entire pair of shoes including the midsole, outsole, tongue, upper and shoelaces, are made from TPEE (pellets, yarn, or monofilament), the goal of recycling the entire shoe as a unit of the same material can be achieved. Furthermore, since PET and TPEE belong to the same family, an upper made of PET monofilament can be combined with other shoe components made of TPEE without encountering recycling issues. The use of single materials or materials from the same family simplifies and streamlines the recycling process.

Specification of TPEE Monofilament

Many office chair and shoe manufacturers are currently incorporating TPEE monofilament into their products. This is mostly due to the exceptional elasticity, flexibility, abrasion resistance, and physical properties of TPEE monofilament. It provides a comfortable user experience for shoe and office chair application. Furthermore, TPEE monofilament is characterized of its good fatigue resistance. It will return to its original state after being stretched and relaxed repeatedly. This increases the lifespan of its application.

Material: TPEE

Color: Transparent or customized color

Country of Origin: Taiwan

Cross Sectional shape: Circle

Main Application: Footwear, office chair

Diameter: 0.12mm~0.2mm

Denier: 90D~360D

The diameter and physical properties (including breaking strength/Elongation and hot air/boiling water shrinkage) of Monofilaments could be modified according to costumers’ needs.

Application-Footwear

TPEE (Thermoplastic Polyester Elastomer) has recently been a hotly discussed and widely applied material in the footwear industry. It can be used in every part of a pair of shoes including the tongue、upper、insole、outsole、shoelaces and so on. Take the upper for example. TPEE monofilament can be used to weave the upper part of shoes. It possesses five characteristics, which are listed below:

Elasticity and Flexibility: Outstanding elasticity and flexibility enhances wearer’s comfort

Transparency: Due to the transparent feature of TPEE monofilament, it provides good sense of transparency when applied in weaving upper of shoes

Abrasion Resistance: TPEE monofilament’s excellent abrasion resistance allows it to tolerate continuous use and friction

Lightweight: TPEE mono-fabric can be lightweight while still maintaining strength through the design of fabric structure

Recyclability: As TPEE can be applied in every parts of the shoe, the recycling process is simplified

In conclusion, TPEE monofilament is suitable for weaving upper fabric of shoes due to its characteristics of elasticity, flexibility, transparency, abrasion resistance, lightweight and recyclability.

English

English Français

Français Deutsch

Deutsch Русский

Русский Português

Português Italiano

Italiano हिन्दी

हिन्दी Español

Español Nederlandse

Nederlandse العربية

العربية Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Bahasa Indonesia

Bahasa Indonesia বাঙ্গালী

বাঙ্গালী Türk

Türk 繁體中文

繁體中文